About Us

Family owned and operated

More than 60 years ago, Colonial Press International was founded on the simple principle of providing the best quality and value to our customers, and becoming a reliable printing resource for their success.

The result today has been an expansive base of technology and experienced professionals with a keen insight in all aspects of printing and distribution.

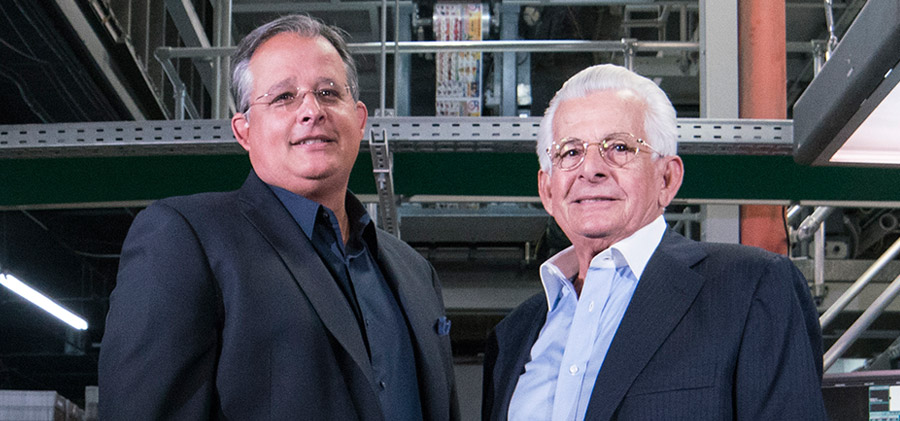

Still independently owned and managed by the Gomez family, Jose and Jorge continue to embrace a customer- focused, entrepreneurial strategy providing growth and opportunities for our customers and employees.

Our Story

Jose’s son, Jorge Gomez, joined Colonial Press as President. Jorge graduated from Florida International University in 1992 with a Bachelor of Accounting degree, followed by 5 years as a Senior Auditor for KPMG Peat Marwick.

Jorge, like his father before him, became President and CEO of Colonial Press International. Together they developed a long-term business plan for the continued growth of Colonial Press.

Colonial Press was nominated and certified as a National Corporate Plus Member of the NMSDC by Wachovia Bank. Colonial Press is proud to operate as the only Commercial printer with this certification. Learn More

Installation and implementation of the Prism WIN Management Information System. Providing a secure closed IT system integrated with accounting, estimating, planning, real time scheduling, direct machine interfaces on all printing equipment, inventory management, and integration with our logistic partners.

Colonial Press purchased and installed a new Goss Sunday 3000 press, a $15M investment. The press has tripled the press manufacturing output of the facility and provides our customers major production efficiencies, reducing their costs and improving time-to-market. Designed as a commercial press it was customized with many unique features.

Continued investment and growth with new and existing customers creates a 20% increase in employment at Colonial Press. This growth allows for major equipment to move to 24 hour, 7 day production schedule.